Thermo-Ultrasonicator (Sonic VCX-500)

The 500-watt thermo-ultrasonicator is equipped with a modified 20 kHz high-temperature ultrasonic horn and a hotplate, capable of operating up to 175℃. Its microprocessor-based system allows up to 10 user-programmed protocols and automatic amplitude compensation.

Split Tube Furnace (Thermolyne 79300)

Engineered for high-temperature applications up to 1,200℃, this furnace offers uniform thermal treatment via its cylindrical heating chamber and gradient thermal treatment through partial tube insulation.

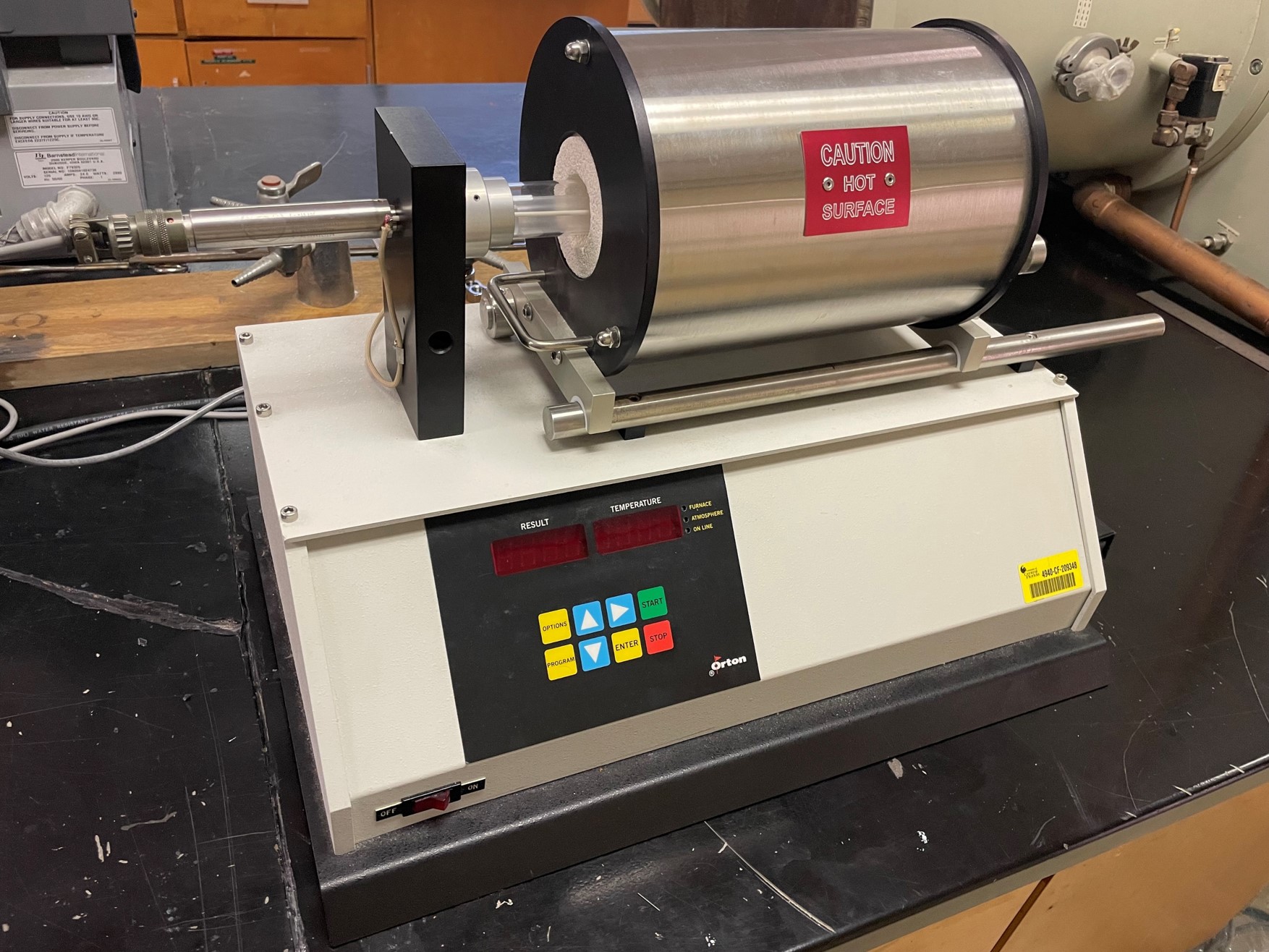

Dilatometer (Orton 2010B)

The dilatometer automatically measures the linear change of a sample under controlled heating/cooling (up to 1,000℃) with an integrated furnace, sample holder, measuring head, and control interface.

Polishing/Grinding, Sectioning & Cutting Blade

Our lab houses advanced tools for chalcogenide materials. The polishing/grinding machine offers variable speeds (100-1000 rpm) with precise control, and the gravity-fed precision sectioning machine ensures delicate, accurate cuts. This includes our cutting blade for precision sample preparation.

Glovebox (Mbraun MB 150-GI)

Our glovebox maintains a non-reactive atmosphere (<1ppm moisture and oxygen) using a closed-loop circulation system, ensuring safe handling of sensitive materials.

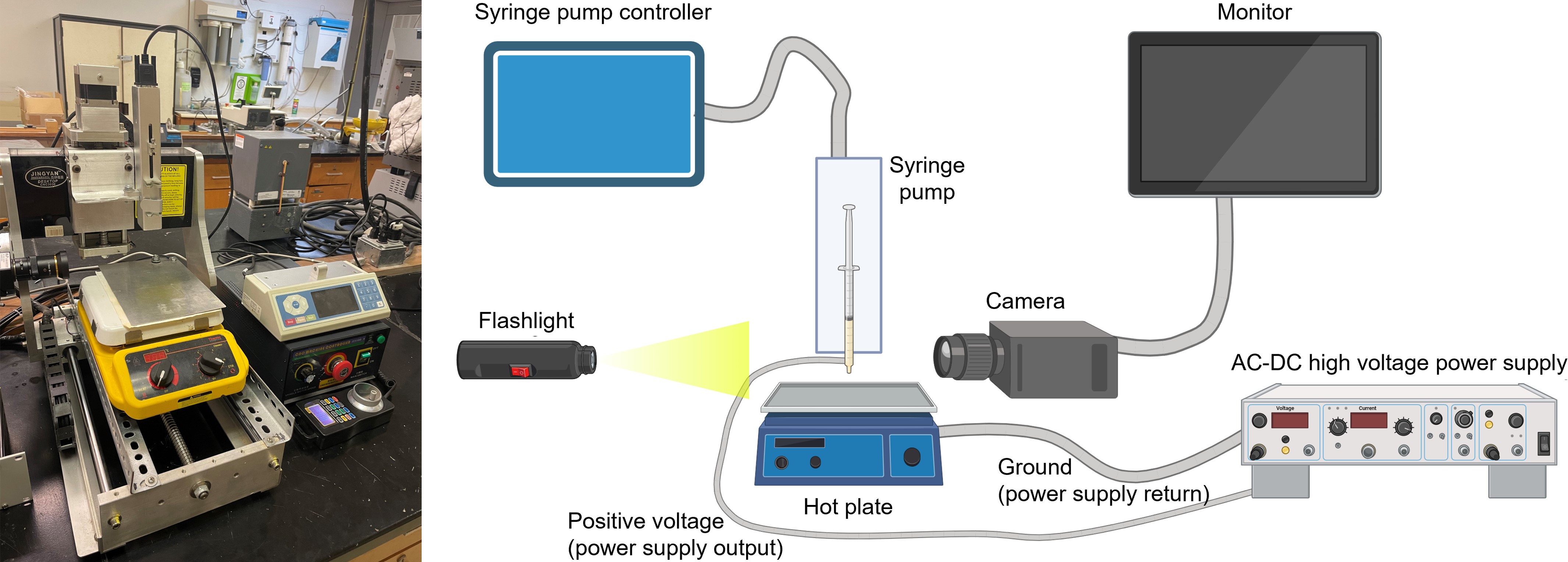

3-D Programmable Electrospray Deposition Station (Customized)

This fully customized tabletop system uses high voltage to atomize a solution into micro-droplets, depositing them into a tunable 3-D structure for creating films with precise characteristics.

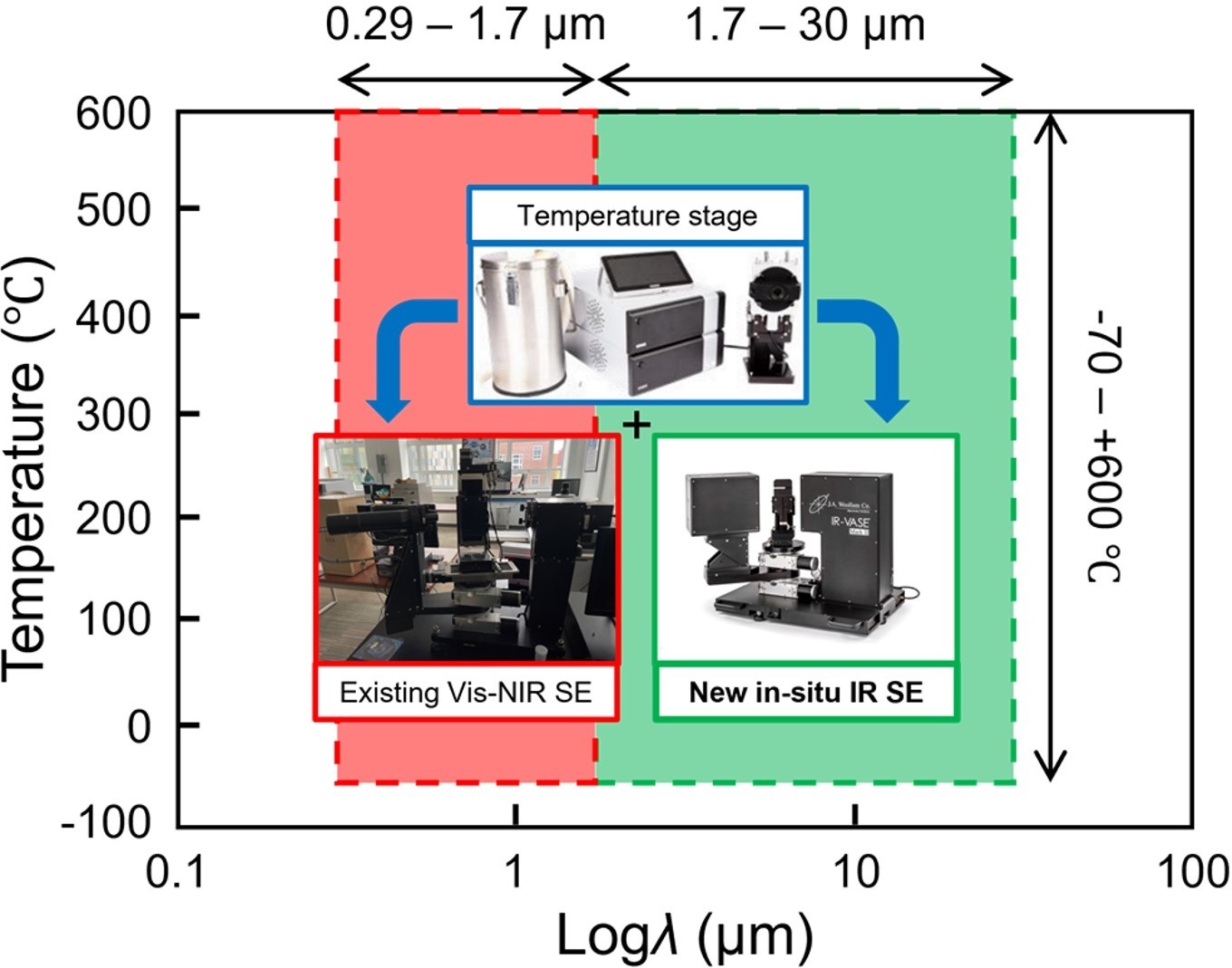

In-situ Infrared Spectroscopic Ellipsometer

Our J.A. Woollam’s infrared variable angle spectroscopic ellipsometer (IR-VASE Mark II), equipped with a modular temperature stage (Linkam HFSEL 600). The instrument supports spectral and temperature ranges of 1.7 to 30μm and -70 to 600℃, respectively. The IR SE system is combined with UV-Vis system (J.A. Woollam’s VB-400) with a spectral range of 293nm to 1.7μm. Here, a set of two data from the combo system can be stitched and collectively analyzed by their operating software to generate index dispersions over a broadband spectral range of 293nm to 30μm. Also, the temperature stage is compatible with both ellipsometers, making the combo configuration capable of providing dispersion data in a wide thermo-spectral window.

High Performance fume hoods (Labconco)

The laboratory fume hood from Labconco offers a wide range of solutions tailored to different needs. This includes standard chemical fume hoods for strong containment, floor-mounted models that provide spacious interiors with excellent ventilation, and special-application hoods made from PVC or stainless steel for work involving perchloric acid, acid digestion, or radioisotopes.